JMDM | IPD For exclusive iron detection use system

Installation Type Iron Piece detector

For exclusive iron detection use.

USE

Textile (non-woven, knit fabric, dyeing and finishing, carpet, lace), Apparel・Sewn product, Sanitary material, Paper・lumber (pulp, paper container), Chemistry (rubber・plastic・film), Recycle (PET bottle, construction waste

●Installed to production line or fabric inspection machine for wide products such as paper, textile, carpet,

non-woven material or felt etc.

This machine can be used extensively for the detection of small ferrous objects such as chips, metallic wear debris, broken cutter blades,

left tools or scissors, fish hooks contained in feed for animals, or in any case where contamination by ferrous objects are prohibited,

contrarily, can also be used for notification of forgotten objects such as an IC tag or a deoxidizer.

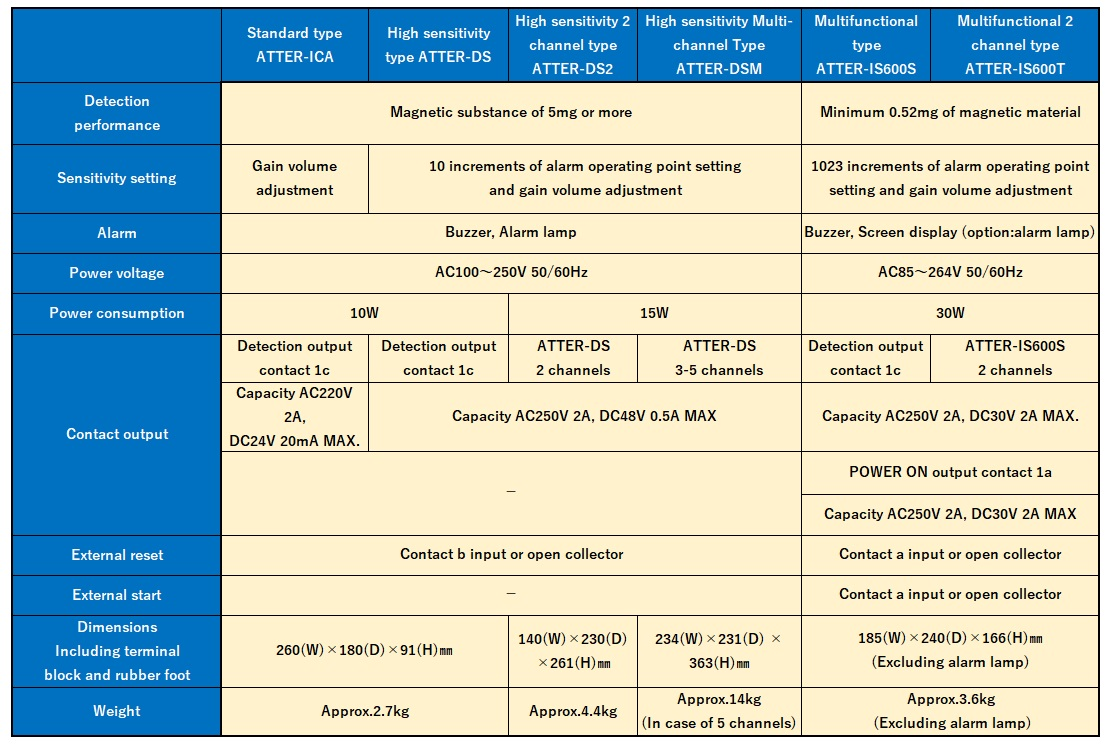

●A variety of controller and sensor options for a wide range of needs.

There are 6 types of IPD system controller by functions. Optimum combination with IPD system sensor can be selected according to

applications. Determination of the model depends on the product, detected metal size requirement, product line speed or installation

environment.

●IPD system sensor is custom-made with short delivery time.

Custom-made and short delivery time (10 business days at earliest) plus optimum IPD system is installed in accordance with product width

requirement and facility conditions.

●Ferrous objects can be detected from a standstill (0m/min) to high speed production line.

The sensor is installed and functions with the generator principle with the combination of magnet and coil. The lower the inspection

passing speed, the higher the electromotive force is required in order to detect ferrous particles sufficiently.

When the product line speed is 10m/min or lower, then the IPD system will give best detecting results in conjunction with the DB

oscillator.

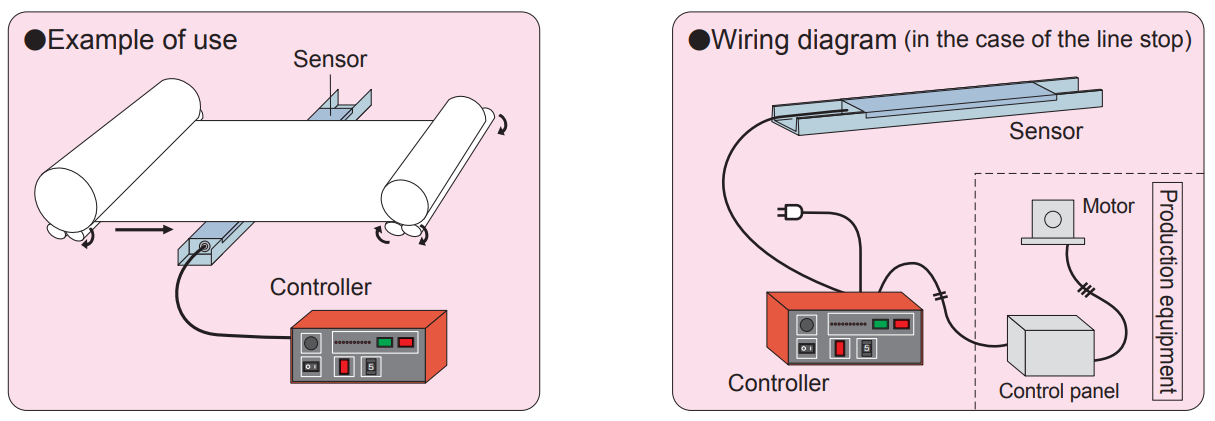

●Product line can be stopped in interlock with IPD system.

Product line can be stopped at detection of a ferrous object by contact output of the controller. (Please see explanation of the controller for

details.) Since marking is performed at detection with the marking device (optional), a ferrous object can be removed post-process.

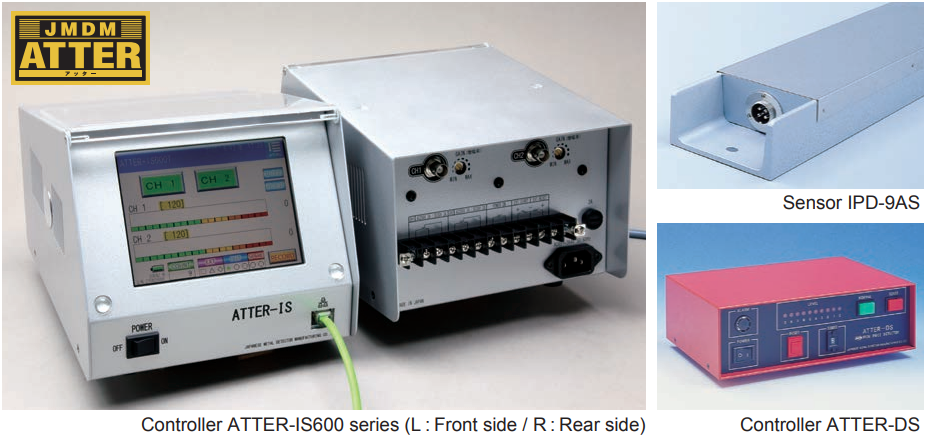

CONTROLLER

ATTER-DS High Sensitivity Type Controller

1. Multifunctional LED readout (LEVEL)

①Signal from sensor ②Alarm operation sensitivity setting (SENSE) ③Noise level are indicated.

2. Gain of amplification can be adjusted finely.

The amplifier built in to the controller amplifies weak signal from sensor at detection enough to process it electrically.

Gain amplification can be adjusted by gain volume on the rear of controller between “low (left)” and “high (right)” finely in adjustment.

It is usually recommended to adjust gain so that the LED readout lights up to the center when ferrous particle to be detected passes through sensor.

3. Alarm operating sensitivity setting(SENSE).

Alarm operating sensitivity for detection can be set in 10 increments from 0 to 9 on the digital switch.

The relevant set value level lights up on LED readout. When the signal from the sensor is larger than or equal to the set value, the alarm is triggered. As the sensitivity is increased, alarm operation is performed with smaller ferrous objects.

The sensitivity can be set to allow ferrous objects smaller than the minimum allowed to pass undetected.

4. Noise level

In some installation locations of IPD system, the sensor may receive electrical signals similar to or the same as the detection signal from nearby machinery etc. Since these signals or “Noise” is other than the detection signal, it may cause “false

detection” when actually there is in fact no ferrous object. The noise filter at the input of amplifier compresses and removes them as noise. However, when the noise is too large, some lamps of super LED readout light up and shows noise level.

When “SENSE” is set to lower detection level (larger numeric value) than noise level, alarm operation is performed with noise.

5. Cassette system high sensitive amplifier

Cassette system high sensitive amplifier built in to controller. It can be removed and replaced easily without controller disassembly even if failure occurs.

ATTER-ICA Standard Sensitivity Type Controller

1. Excellent cost performance long selling ATTER.

2. Differs from the ATTER-DS, alarm operating point is fixed and the size of ferrous particle to be detected is adjusted with amplification rate between high and low.

Multi-channel Controller (used in combination with multi-channel sensor)

ATTER-DS2 2 Channel Type Controller

2 ATTER-DS units integrated into one ATTER-DS2.

ATTER-DSM Multi-channel Type Controller

3-5 ATTER-DS units integrated into one ATTER-DSM unit.

As for ATTER-DSM, cassette replacement of amplifier is not available.

SENSOR

1. Multifunctional LED readout (LEVEL)

①Signal from sensor ②Alarm operation sensitivity setting (SENSE) ③Noise level are indicated.

2. Gain of amplification can be adjusted finely.

The amplifier built in to the controller amplifies weak signal from sensor at detection enough to process it electrically.

Gain amplification can be adjusted by gain volume on the rear of controller between “low (left)” and “high (right)” finely in adjustment.

It is usually recommended to adjust gain so that the LED readout lights up to the center when ferrous particle to be detected passes

through sensor.

3. Alarm operating sensitivity setting(SENSE).

Alarm operating sensitivity for detection can be set in 10 increments from 0 to 9 on the digital switch.

The relevant set value level lights up on LED readout. When the signal from the sensor is larger than or equal to the set value, the alarm is

triggered. As the sensitivity is increased, alarm operation is performed with smaller ferrous objects.

The sensitivity can be set to allow ferrous objects smaller than the minimum allowed to pass undetected.

4. Noise level

In some installation locations of IPD system, the sensor may receive electrical signals similar to or the same as the detection

signal from nearby machinery etc. Since these signals or “Noise” is other than the detection signal, it may cause “false

detection” when actually there is in fact no ferrous object. The noise filter at the input of amplifier compresses and removes

them as noise. However, when the noise is too large, some lamps of super LED readout light up and shows noise level.

When “SENSE” is set to lower detection level (larger numeric value) than noise level, alarm operation is performed with

noise.

5. Cassette system high sensitive amplifier

Cassette system high sensitive amplifier built in to controller. It can be removed and replaced easily without controller

disassembly even if failure occurs.

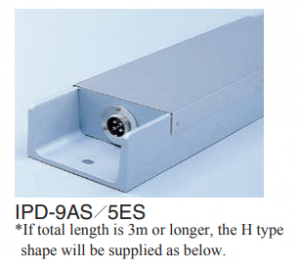

IPD-5ES Standard Type

1. Sensor cover : Stainless steel

2. Usage in combination with oscillator is not available

3. Dimensions (mm) : Approx 100(W) x 50(H) x ordering length

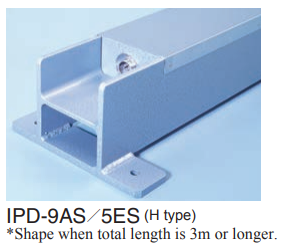

H type / Dimensions (mm) when total length is 3m or longer : Approx 100(W) x 100(H) x ordering length

*Even if total length is under 3m, H type can be manufactured as needed.

*Outer appearances of IPD-9AS and 5ES is the same.

IPD-9AS High Sensitivity Type

1. Sensor cover : Stainless steel

2. When adding oscillator, sensor type is IPD-9ASBT.

3. Dimensions (mm) : Approx 100(W) x 50(H) x ordering length

H type / Dimensions (mm) when total length is 3m or longer : Approx 100(W) x 100(H) x ordering length

*Even if total length is under 3m, H type can be manufactured as needed.

*Outer appearances of IPD-9AS and 5ES is the same.

IPD-11A Ultrahigh Sensitivity Type

1. Sensor cover : Stainless steel

2. Usage in combination with oscillator is not available.

3. Maximum effective width is 2.5m.

4. Dimensions (mm) : Approx 150(W) x 62(H) x ordering length

*Due to its construction, there are some effective widths which can not be manufactured. Please contact us.

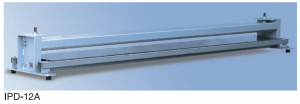

IPD-12A For thick product inspection

1. Tunnel type sensor suitable for thick product to be

inspected. The product can be inspected from above

and below.

2. Sensor cover : Stainless steel

3. Detection area can not be divided.

4. Usage in combination with oscillator is not available.

5. Maximum effective width is 2m.

Maximum detection height is 50mm.

6. Please contact us for dimensions.

- Categories

- NEWS