Light Air – Multi Layer Piping System for Compressed Air

Light Air

Multi‑Layer Piping System for Compressed Air

Overview

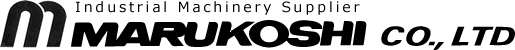

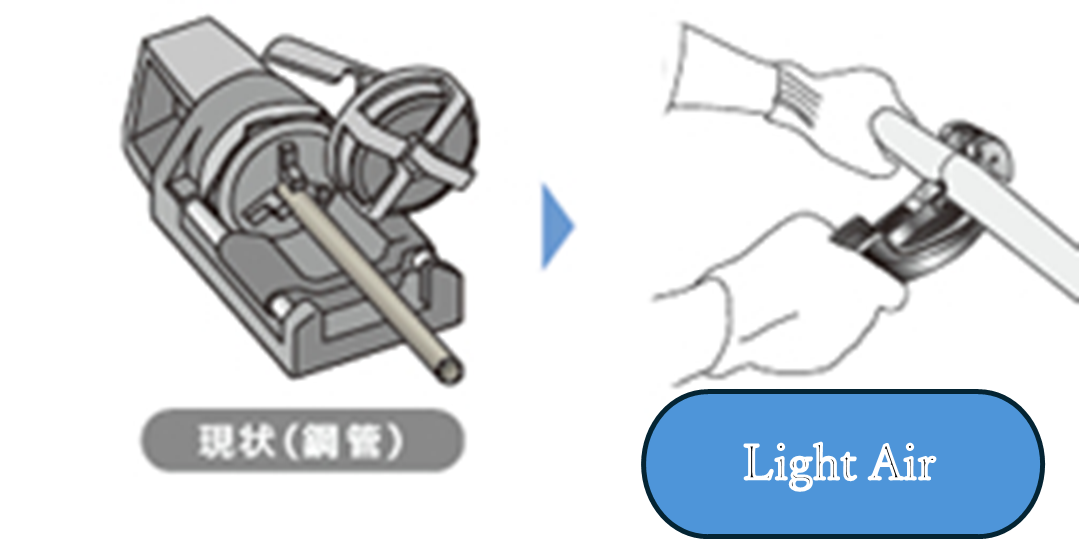

Light Air is a lightweight, corrosion‑resistant three‑layer piping system designed specifically for compressed‑air distribution. Its aluminum‑core composite structure provides excellent durability while remaining easy to handle during installation. Light Air is ideal for factories, workshops, and any facility that requires a clean and reliable air supply.

Key Features

Lightweight & Easy to Handle

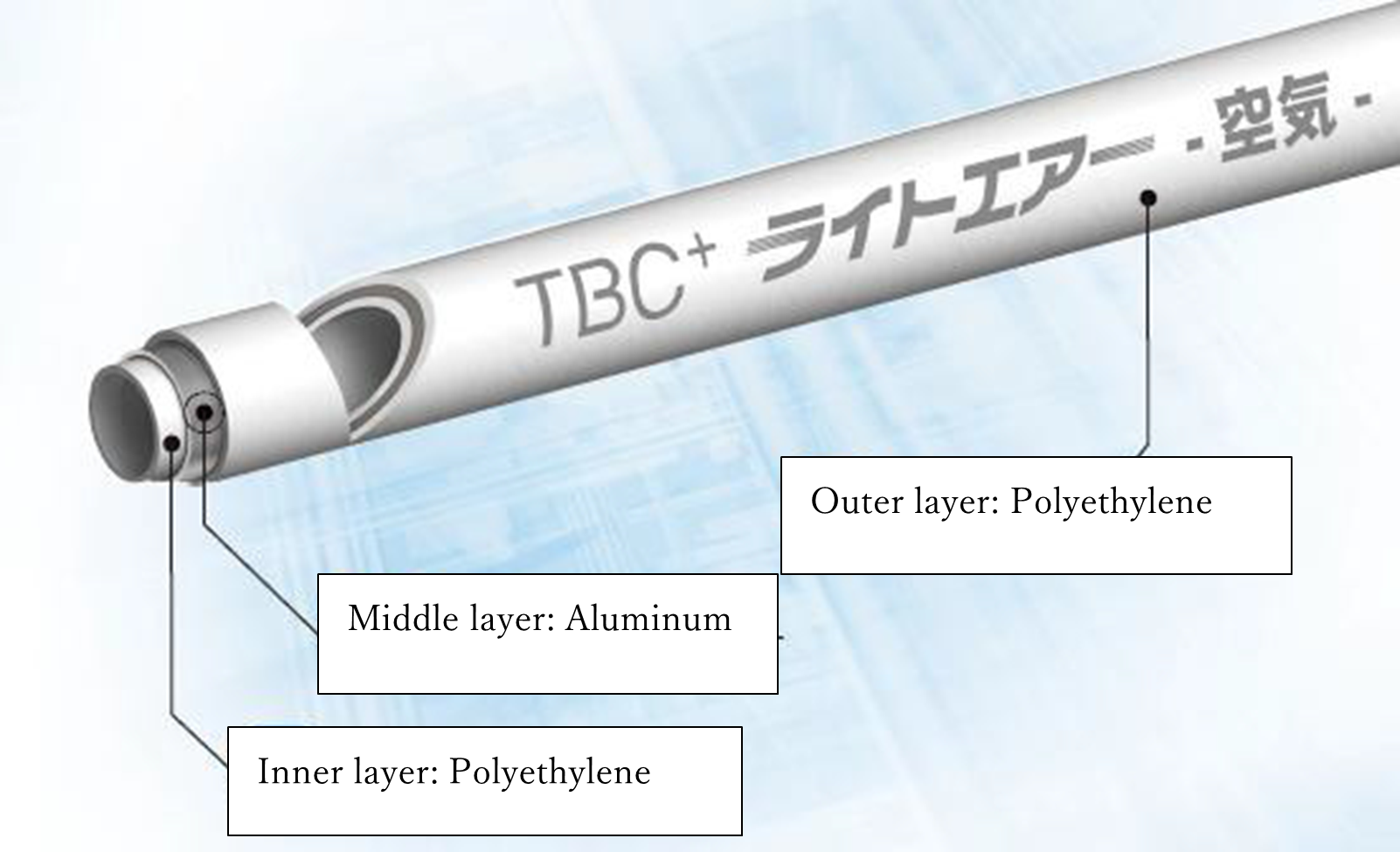

- Significantly lighter than steel pipes

- Reduces load on building structures

• Improves work efficiency during installation

Simple Installation

- No threading required

- Pipes can be cut easily on site

- Assembly requires only tightening the nut—no torque management needed.

Flexible & Shape‑Retaining

- Pipes can be bent smoothly by hand

- Maintains its bent shape without spring‑back

• Reduces the number of fittings needed, minimizing potential air‑leak points

Excellent Corrosion Resistance

- Three‑layer structure (plastic–aluminum–plastic) prevents rust

- Ensures clean, high‑quality compressed air

- Suitable for environments where contamination must be avoided

Recommended Applications

- Factory compressed‑air lines

- Automotive workshops and garages

- Facilities with frequent layout changes

- Food, medical, and precision‑equipment environments requiring clean air

Why Choose Light Air?

Light Air combines the durability of metal with the flexibility and corrosion resistance of resin piping. It offers a modern, efficient alternative to traditional steel air‑line systems, reducing installation time and long‑term maintenance costs.

▼ For more information, please contact us ! ▼

- Categories

- NEWS