Bearings are parts that allow the shafts inside machines to rotate smoothly. They are used in a wide range of fields, including aviation, space, railways, automobiles and motorcycles, machinery, leisure equipment, home appliances, energy equipment, and office equipment, supporting our lives and industry.

A car uses 100 to 150 bearings in the engine, transmission, wheels, etc., and they are essential parts for safe driving. Examples of where bearings are used in a car are shown below.

| Engine

Many bearings are used in engines, auxiliary equipment, etc. |

Electric component

Many bearings are used in alternators, starter motors, car air conditioners, etc. |

chassis

Special bearings are used for suspensions, wheels, etc. |

| Steering

Bearings are used in the rotating parts of the steering column and steering gear. |

Manual Transmission

Ball bearings, roller bearings, and tapered roller bearings are used for shaft support bearings in automotive manual transmissions. |

Automatic Transmission

Needle roller bearings are used in automatic transmissions for automobiles. |

History of bearings

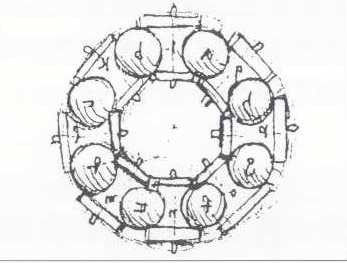

Bearings have a long history, dating back to BC. In ancient Egypt, when building pyramids, heavy stones were transported by placing logs under them. The principle behind bearings is to reduce friction and transport heavy objects lightly.

The basic principles and structure of modern bearings were formed during the medieval industrial revolution. The picture below is a drawing of a bearing drawn by Leonardo da Vinci.

Bearing type

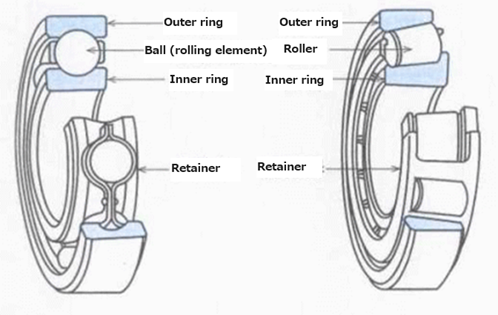

Bearings can be broadly divided into two types: rolling bearings and sliding bearings, each based on different principles of friction. In general, rolling bearings have lower friction when the machine rotates, and rolling bearings have a structure that utilizes rolling friction by using balls and rollers as rolling elements between the outer ring and inner ring. Rolling bearings are easier to maintain than sliding bearings, are commonly lubricated with grease, and have convenient lubrication and sealing devices.

Bearings that do not use balls or rollers are called sliding bearings. There are resin types, metal types, etc. Each material has a variety of characteristics, such as those that are resistant to water and those that do not conduct electricity.

Bearing makers list that we mainly handle.

| No. | Maker |

| 1 | NTN |

| 2 | NSK |

| 3 | KOYO |

| 4 | NACHI |

| 5 | NMB |

| 6 | ASAHI |

| 7 | FYH |

| 8 | OZAK |

| 9 | THK |

| 10 | DAIDO |

| 11 | IKO |

| 12 | OILES |

| 13 | SANKYO OILLESS Industry |

| 14 | DAIDO METAL |

| 15 | ASK |

| 16 | BANDO |

| 17 | TSK |

| 18 | FREEBEAR |

| 19 | EZO |

| 20 | NB |

Reference

- Electricity Units List with Analogy (Water Flow)

- Measurement Unit Conversion Table

- Micrometer handling and maintenance tip

- Pipe Size Comparison Table (配管サイズ比較表)

- Pressure Conversion Table (圧力換算表)

- Voltages & Frequencies List by country(世界の電源事情)

- What is Bearing??

- What is pressure? What is a pressure gauge??

- What types of pumps are there?

- World Calendars

- Specifications List of Premium Efficiency Motors (Compliant with JIS C 4213:2014)

We will provide the future of customers.(81)467-87-1552

Inquiry Please send E-mail