NACHI DLC-REVO Drills Burrless

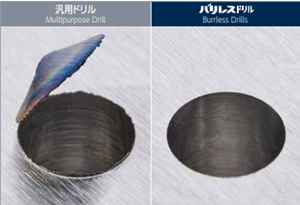

Better to have no burrs from the beginning.

- Developed Non-Ferrous Metals such as Aluminum alloy with large burrs and weld.

- The shape is optimized for use in Non-Ferrous Metals, while taking advantage of the Burrless concept.

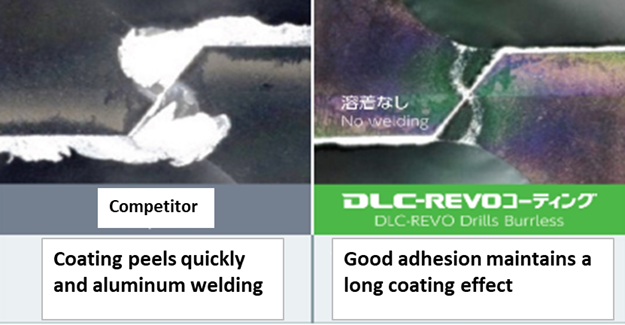

- Newly developed DLC-REVO coating reduces welding.

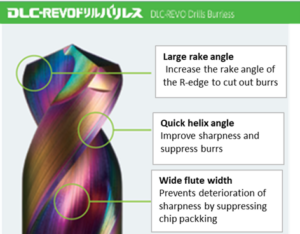

1. Optimized shape for Non-Ferrous Metals

- The shape follows the Radius Edge and Center Pont of the burrless drill.

- Large rake angle and quick helix angle improve sharpness and suppress the formation of burrs.

2. “DLC-REVO coating" revolutionizes the processing of Non-Ferrous Metals

- Improved lubricity and welding resistance of DLC coating.

- Improved wear resistance and adhesion to achieve long life even in high-speed cutting.

- Thin film of 1µm or less has sharp cutting edge and excellent cutting quality.

3. Burrless series with a full range of products

The Aqua REVO Drill, previously introduced in Industrial News, is now also available in a burrless type.

The Aqua REVO Drill is for steel and cast iron, while the DLC-REVO Drill is for non-ferrous metals.

In addition, the Burrless series also includes a lineup of taps and end mills.

You can check the catalogs of the Burrless series from the following links.

- Categories

- NEWS